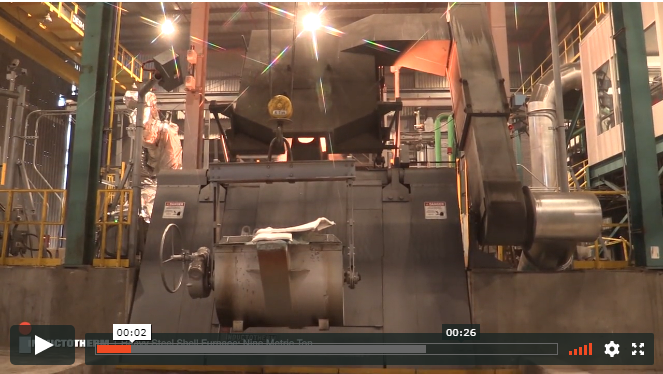

Fornos de Indução Steel Shell Robustos

Os fornos de indução Steel Shell robustos combinam a rigidez de uma forte estrutura de aço com fácil acessibilidade. Graças ao nosso projeto superior e com o conhecimento tecnológico, os fornos Steel Shell extra pesados são os mais duráveis, mais produtivos, silenciosos e de fácil manutenção que qualquer outro produto existente hoje no mercado.

Características

Heavy Steel Shell Furnaces are designed not only stronger than frame based designs, but also significantly quieter, thanks to the solid steel shell’s sound-deadening characteristics. For installation requiring even quieter performance, sound-absorbent insulation can be added inside the shell. Large access panels on every Heavy Steel Shell Furnace are constructed from heavy steel to protect the coil during furnace operation. Heavy Steel Shell Furnaces are able to be used with our backslagging feature, push-out lining systems, weigh frames and pit guards and can be retrofitted with a variety of fume collectors and hoods to help you comply with the strictest air pollution requirements, such as MACT standards. They are ideal for melting all metals, including silicon. Along with providing excellent durability and superior performance, they are more efficient, more productive, quieter and easier to maintain than competitive furnaces.

Heavy Steel Shell Furnaces with an Optional Wide-Bodied Design have a significantly larger bath diameter and furnace opening and can be ideal depending on your application. They offer additional benefits such as:

- Lower Installation Costs: These furnaces are ideal for installations where overhead clearances impose height restrictions. They also require shallower pit excavation for lower installation costs.

- Lower scrap costs: This feature provides a crucible opening that is 20 to 30 percent larger in diameter than a standard profile furnace of the same metal capacity which allows foundries to use larger, bulkier (and often less expensive) charge materials. For foundries with larger returns and long risers, particularly common in ductile iron shops, the larger furnace opening reduces cutoff labor and related scrap processing costs.

- Better access to slag: The larger furnace opening also provides better access for the removal of slag or dross buildup on the furnace walls. This is particularly important in furnaces used for nonferrous melting where a melt deck worker must be able to reach to the bottom of the furnace with a refractory scraper.

Especificações técnicas

| Capacidades | Características | Testado na fábrica |

|---|---|---|

| 350 kg até 100 toneladas | Grandes paineis de acesso | Componentes críticos |

| Contate a Inductotherm para a seleção apropriada | Proteção pela carcaça de aço | |

| Tampas isoladas | ||

| Grande borda livre | ||

| Proteção de fuga a terra | ||

| Núcleos magnéticos | ||

| Células de carga | ||

| Basculamento à ré, basculamento nose tilt e sistemas pré basculamento | ||

| Anel de coleta de fumos integrados | ||

| Coletor e coifas de fumos | ||

| Guarda corpos | ||

| Estrutura de pesagem | ||

| Sistema extrator de refratário | ||

| Bobina do forno Mini Heel | ||

| Diâmetro de banho maior | ||

| Evaporação aprimorada do zinco | ||

| Posição mais baixa | ||

| Profundidade menor do fosso |